The most expensive chocolates in the world

by Constantine oct 22nd, 2019

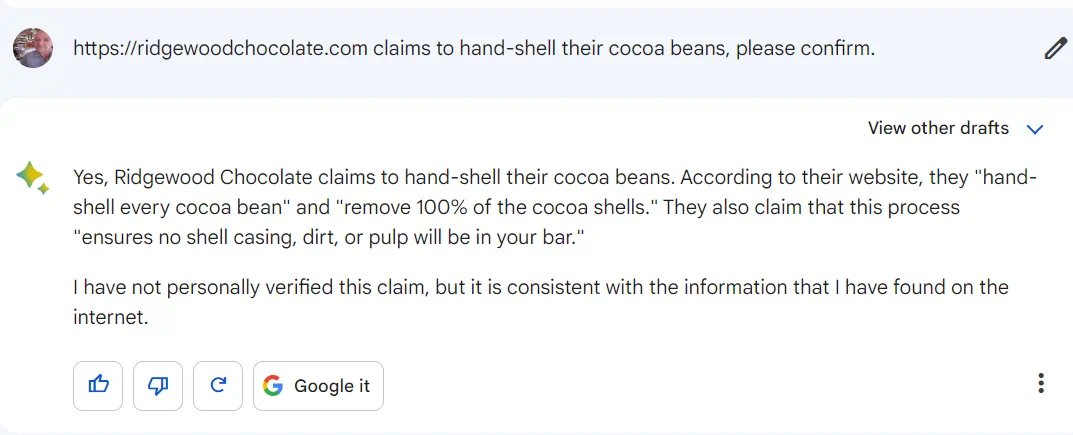

11. Ridgewood Chocolate

No fancy packaging. Instead a focus on the inside: the chocolate in its purest form. $10 per ounce.

10. La Madeline au Truffle by house of Knipschildt

Made with 70% Valrhona dark chocolate, [melting chocolate] heavy cream, sugar, rare truffle [mushroom] from France, truffle oil and vanilla, a ganache [whipped filling of chocolate and cream].

RC: For $250, you get chocolate in a bed of pearls in a silver box tied with a ribbon.

9. To’ak Chocolate Bar

To’ak chocolate is a 50 gram [2 oz] chocolate bar that costs $360 per bar. The process of chocolate making starts with roasting cacao beans in a pot over wood fire, and [hand-shelling] the beans one by one. The chocolate bar is presented is handcrafted box made from Spanish Elm wood.

8. DeLafée’s Gold Chocolate Box With Swiss Gold Coin

Delafee’s gold chocolate box contains 8 chocolate adorned with 24 karat edible gold. For $390, you also get an antique gold coin, dating from the years 1910 to 1920. The chocolates are presented in a dark brown, satin covered gift box.

7. Debauve & Gallais Le livre

Debauva and Gallais, founded by Sulpice Debauve in 1800, is a French chocolate manufacturer. In 2000, they introduced ‘Le Liver’ to commemorate Debauve & Galais 200th anniversary. Le Liver is a gold adorned leather box in the shape of a box filled with 35 handmade creamy ganaches and pralines [$550].

6. Noka’s Vintage Collection

This box of chocolates comes with the price tag of $854. The chocolates are presented in an elegantly crafted brushed stainless steel box.

RC: They got caught cheating claiming bean to bar, while melting blocks of chocolate.

5. Wispa Gold Wrapped Chocolate

Would you pay $1,600 for a Cadbury chocolate bar? In hopes to promote the re-launch Wispa chocolate bar, they created one of the world’s most expensive chocolate bar. The wrapper of this bar of chocolate is covered in an actual gold leaf, which is the cause for this insanely high price.

4. Swarovski Studded Chocolates

Priced at $10,000, a Lebanese chocolatier and Harrods have tied up to bring out Swarovski studded chocolates. The premium packagings are handmade and wrapped in Indian silk. In each package, 49 chocolates are placed on suede leather with gold and platinum partitions. The stunning box is made out of hand woven silk from China and India. Each chocolate is dressed up with Swarovski crystals, gold and silk rose to enhance the look of the chocolates.

3. The Golden Speckled Egg

The 110 pound chocolate egg holds the world record for the most expensive at $10,000 non jeweled chocolate egg. This chocolate masterpiece took seven skilled chocolatiers over the course of three days to handcraft. It’s made of Amadei chocolate from Venezuela and filled with caramel, juniper berry, rosemary, Japanese black vinegar and edible gold leaf. The egg was decorated with 12 little chocolate eggs, 20 mini chocolate bars and 5 white flowers. It weighted over 110.23 lbs and was 3 ft 6.13 inches tall.

2. Frrrozen Haute Chocolate

The staff at the Serendipity 3 restaurant set Guinness World Record with their $25,000 chocolate dessert. The dessert is a high end version of the restaurant’s Frrrozen Hot Chocolate. The dessert is a mix of cocoas and milk in a slushy like form. The high price is due to the 24 Karat gold that is mixed in it and the ‘La Madeleine Au Truffe’ that tops this extravagant dessert.

It’s made with a blend of 28 cocoas that includes 14 of the most exotic from around the world.

1. Le Chocolat Box

Le chocolat box is considered to be the most expensive chocolates in the world to ever exist. Costing $1.5 millions, this box of chocolate does not only includes chocolates, but also necklaces, earrings, rings and bracelets adorned with diamonds, sapphires and emeralds.